Hand and finger injuries are among the most common injuries in rigging, especially in the oil and gas industries. This is because riggers often touch, manipulate, and rig the load with their hands.

Have you noticed that the most common accidents in your facility involve employees’ hands and/or fingers? This is probably because your riggers use their hands, rather than a tool, to manipulate loads with pinch points.

No touch hand tools are used to control the load from a distance, without physically touching the load. This is particularly useful in situations where a rigger may be at risk to get their hand pinched by or caught in the load.

If you are unfamiliar with what no touch hand tools are and how they are used, you have come to the right place. Continue reading this article to learn more about:

- What no touch hand tools are

- Reasons to use no touch hand tools

- Types of no touch hand tools

- When to use no touch hand tools

What Are No Touch Hand Tools?

No touch hand tools are simple, easily maneuvered products used to manipulate a load without physically touching it. Usually, they resemble a short metal rod with a hook on the end. However, they come in many forms.

No touch hand tools are not rated for any Working Load Limit (WLL) and are strictly used to help facilitate safe movement of a lifted load.

Reasons to Use No Touch Hand Tools

There are three main reasons to utilize no touch hand tools as part of your lift plan.

- Avoid hand injury

- Load control

- Maintaining safe distance from the load

Avoid Hand Injury

No touch hand tools are used to handle a load containing pinch points that is not safe to touch or manipulate with your hands. Rather than a rigger using their hands directly on the load, they can use a tool to hook, wrap, or grab the load.

Load Control

No touch hand tools are also used to position and control a load that may sway, spin, or otherwise require handling to maintain proper load control. They are used in similar situations that a tagline may be implemented. No touch hand tools are, essentially, shorter, rigid taglines.

Maintain Safe Distance from the Load

Riggers may also use no touch hand tools to maintain a safe distance from the load. This is useful if the situation calls for a rigger to be out of the danger zone or fall zone. Again, this is a similar application to how a tagline is used.

Types of No Touch Hand Tools

No touch hand tools typically resemble a metal rod with a hook on the end used for connecting to the load. There are no specific designations that refer to different “types” of no touch hand tools. However, there are many different configurations and adaptations of no touch hand tools used for safe rigging.

No Touch Hand Tools Sold at Mazzella

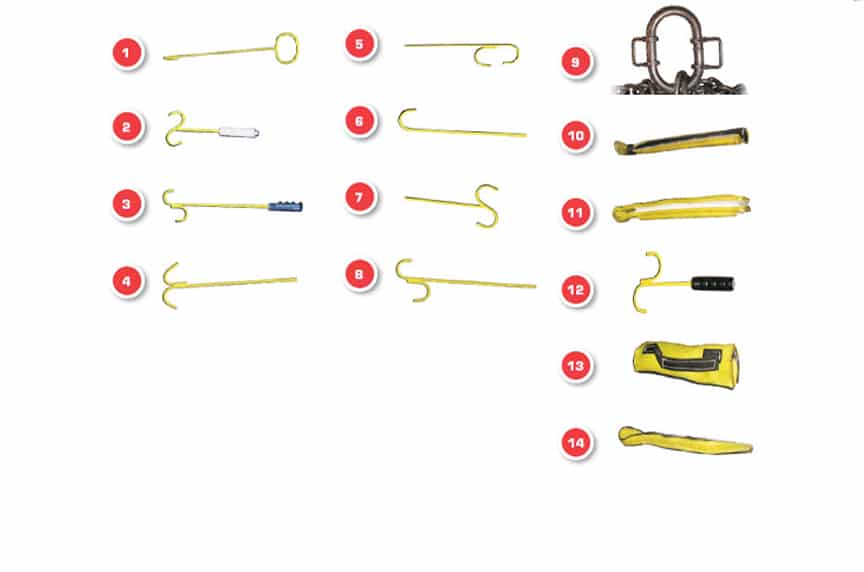

In the image here, you can see all of the kinds of no touch hand tools sold by Mazzella.

The tools labeled #1-8 in the image above are examples of what can be referred to as rigid taglines. As you can see, each of these tools consist of a metal rod with varying types of hooks attached to the end. These no touch hand tools are used for very similar reasons as a tagline—to help control the load from a distance. However, they are not made of rope, less flexible, and are shorter than a comparable tagline.

Note: Rods on no touch hand tools can be custom fabricated to any length.

Tool #9 is an example of an adaption of a no touch hand tool. Essentially, this is a master link with handles. The purpose of this is so the rigger can grab, lift, and maneuver the link onto the crane hook without risk of injuring their hand or fingers.

Tools #10 and #11 are used in the same way as #1-8, except a polymer rod is placed inside of this soft covering.

Tool #13 is used to wrap around a chain or chain sling to eliminate the pinch points between the links. Tool #14, a web sling material with velcro, can be used as an attachment point as well.

As you can see, there are many different configurations a no touch hand tool may come in. However, they all serve the same basic purpose—to provide safety and distance from the load.

Adaptations of No Touch Hand Tools

Similar to the modified master link we mentioned above, no touch hand tools can be adapted to virtually any lift. Most often, we see adaptations of no touch hand tools added to below-the-hook lifting devices in the form of a handle.

Like a traditional no touch hand tool, these modified handles make it easier and safer for the rigger to handle the equipment.

When To Use No Touch Hand Tools

A lot of times we get asked “When am I required to use a no touch hand tool?” No touch hand tools are part of any good risk management or lifting plan, but are not specifically required or mandated by OSHA or ASME.

The Occupational Safety and Health Act of 1970 states that, in the absence of a specific OSHA standard addressing a hazard, employers are required, by the statute’s “General Duty Clause” (Section 5(a)(1)), to protect employees from serious recognized hazards. In cases where the load is unsafe—significant risk of hand injury or losing control of the load—by this definition, it is required to utilize a no touch hand tool or tagline to mitigate the risk.

Wrapping It Up

No touch hand tools are exactly what they sound like—tools a rigger uses to avoid touching the load with their hands. There are three main reasons no touch hand tools are used:

- Avoiding hand injury

- Load control

- Distance from the load

While there aren’t any specific types of no touch hand tools, they do come in varying configurations and are often adapted to work specifically with the device being used.

No touch hand tools can be used as part of virtually any lift plan. While there is not a mandate that specifically requires the use of no touch hand tools, they become necessary when distance from the load is required to keep the rigger safe and maintain load control.

At Mazzellas, we sell a variety of different no touch hand tools among other complete rigging solutions. We also have a team of engineers and welders that can design and fabricate a custom lifting device for you. To schedule a consultation with one of our Lifting Specialists, contact us today.

No Touch Hand Tools

Are you looking for tools to keep your workers safe while making lifts? We offer a variety of no touch hand tools to help keep you away from pinch points and at a distance away from the load. All devices are available in various lengths and handle types.

Contact a sales representative if you need no-touch hand tools!

Copyright 2020. Mazzella Companies.